- Most popular Fakopp product among arborists

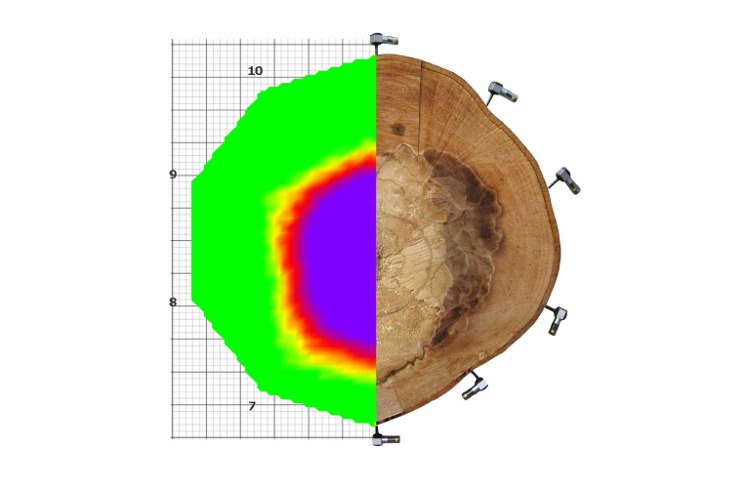

- Detects the size and location of decayed or hollow regions

- Works fast: a measurement can be completed in 5-10 minutes

- Creates a 3D model of the trunk with multiple layers of measurement

- Customizable wind load modeling is included in the software

- Utilizes non-destructive technique using sound waves (no radiation)

- For trees with thick bark, 12 cm long nails are also available

ArborSonic 3D Acoustic Tomograph

Package contents

- SD02 Piezo transducers

- Amplifier boxes

- Battery box

- Cables to connect amplifier boxes and battery box

- Sensor remover tool

- Tape measure

- Steel hammer for tapping transducers

- Rubber hammer for mounting the transducers

- Peli case

- 2pcs. of rechargeable 9 V block batteries

- Battery charger

- User’s manual

- ArborSonic 3D Software

- Caliper for measuring sensor positions (optional)

Usage instructions

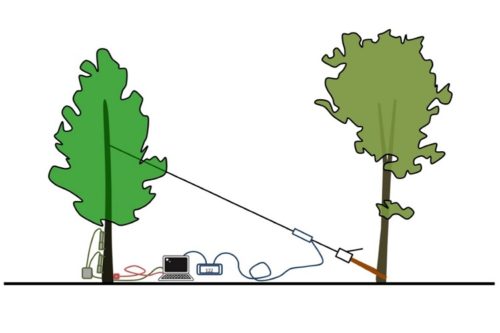

- Drive the transducers through the bark using a rubber hammer with even spacing around the trunk.

- Measure the distances between the transducers with a caliper and enter the measured data to the computer.

- Tap each transducer with a steel hammer to generate sound waves. ArborSonic 3D measures the travel times with microsecond precision to each transducer and transmits the data to the computer.

- The software calculates and displays the internal sound-velocity distribution of the tree.

- Measurements taken at various heights can be assembled into a 3D model.

Technical specifications

Measured time precision

± 2 microseconds

Sensor

Low noise SD02 piezo sensor

Number of sensors

Variable from 8 up to 32

Amplifier box size

127 x 58 x 25 mm

Power consumption

240 mW

Power supply

Standard (rechargeable) 9V block battery

Continuous operation time *

Approximately 2 hours

Carrying case

Peli Case 1500EU

Total weight **

6 kg

PC connection

RS232 over cable or Bluetooth

Data transmission time per sensor tap

Below one sec

Total measurement time of one tree ***

20 minutes

Operating temperature range

0-40 °C

*with one battery

**without PC, including case, hammers and 10 sensors

***one section, including assembly, geometry registration, tapping and disassembly, using 10 sensors